Technical Bulletin July 2024

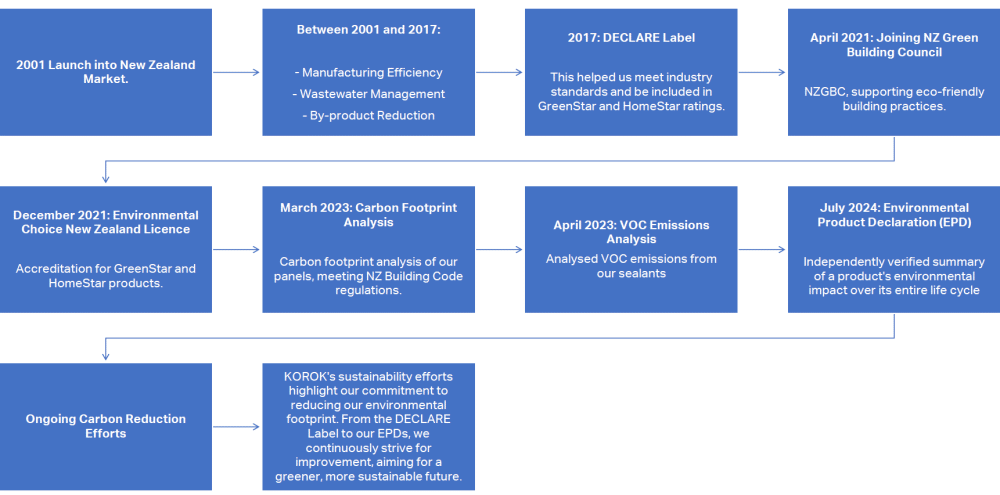

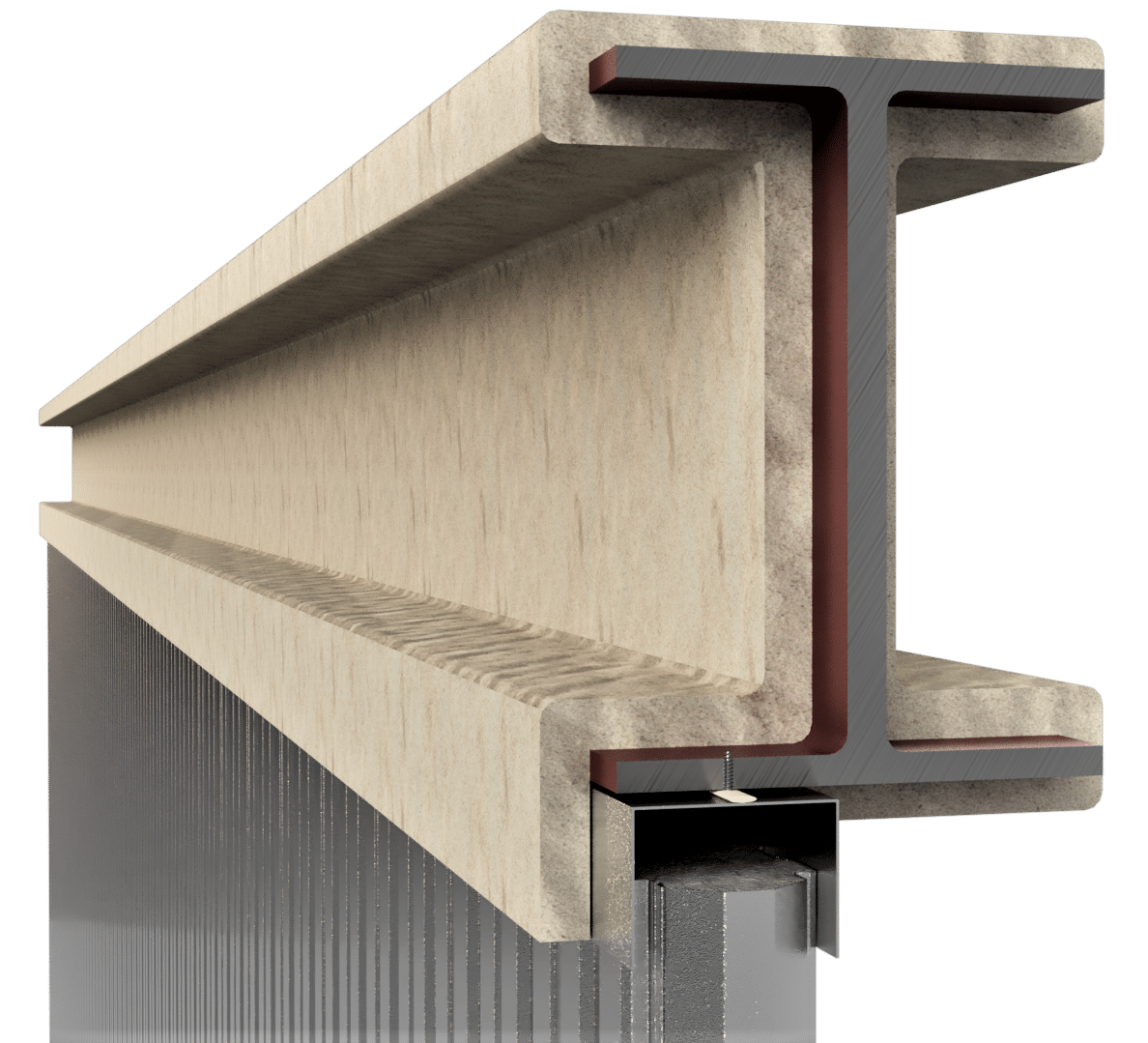

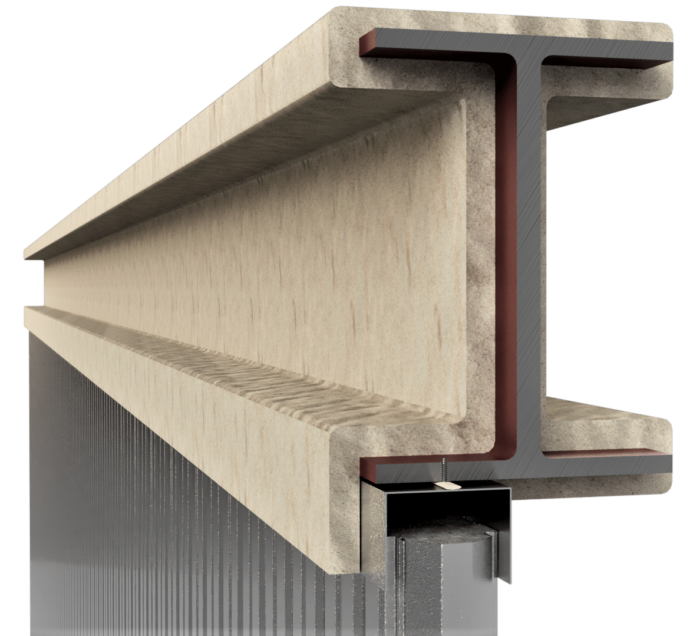

KOROK has a culture of investing in product testing across our core market segments, believing in developing systems that simplify construction with robust, evidence-based performance.

As our market evolves, so does the demand for high-performance, compliant systems. KOROK continually strives to stay ahead, providing evidence-based solutions, supporting documentation, technical support, and literature to the New Zealand Construction Industry.

Our technical team, led by David Cornelius, brings a wealth of experience and a deep passion for the KOROK brand. We balance product innovation, testing, and technical support, ensuring that the industry benefits from practical, test-based solutions.

Pathway to testing:

KOROK collaborates with leading institutions such as BRANZ, Auckland University Acoustics Testing Services, CSIRO, and Warringtonfire Australia, alongside industry-leading fire and structural engineers, manufacturers, and consultants. This collaboration aims to deliver performance-based solutions that meet ever-evolving design requirements.

The testing process begins by identifying industry challenges, followed by setting objectives and the steps required to facilitate a solution. KOROK evaluates both suitability and compliance requirements while considering simple installation methodologies. A systematic evaluation of needs leads to a well-structured test program and assessments.

David and his team rigorously assess and refine processes, aiming to provide the market with simple, high-performance systems and applications that enhance both functionality and efficiency. Our goal is to ensure that every product meets the highest standards of performance and reliability.

Recent Articles

Stay in the loop

Sign-up to our newsletter to be notified of updates.