Smart Wall Solutions for High-Performance Healthcare Environments

KOROK: There’s No Substitute for Tested Performance

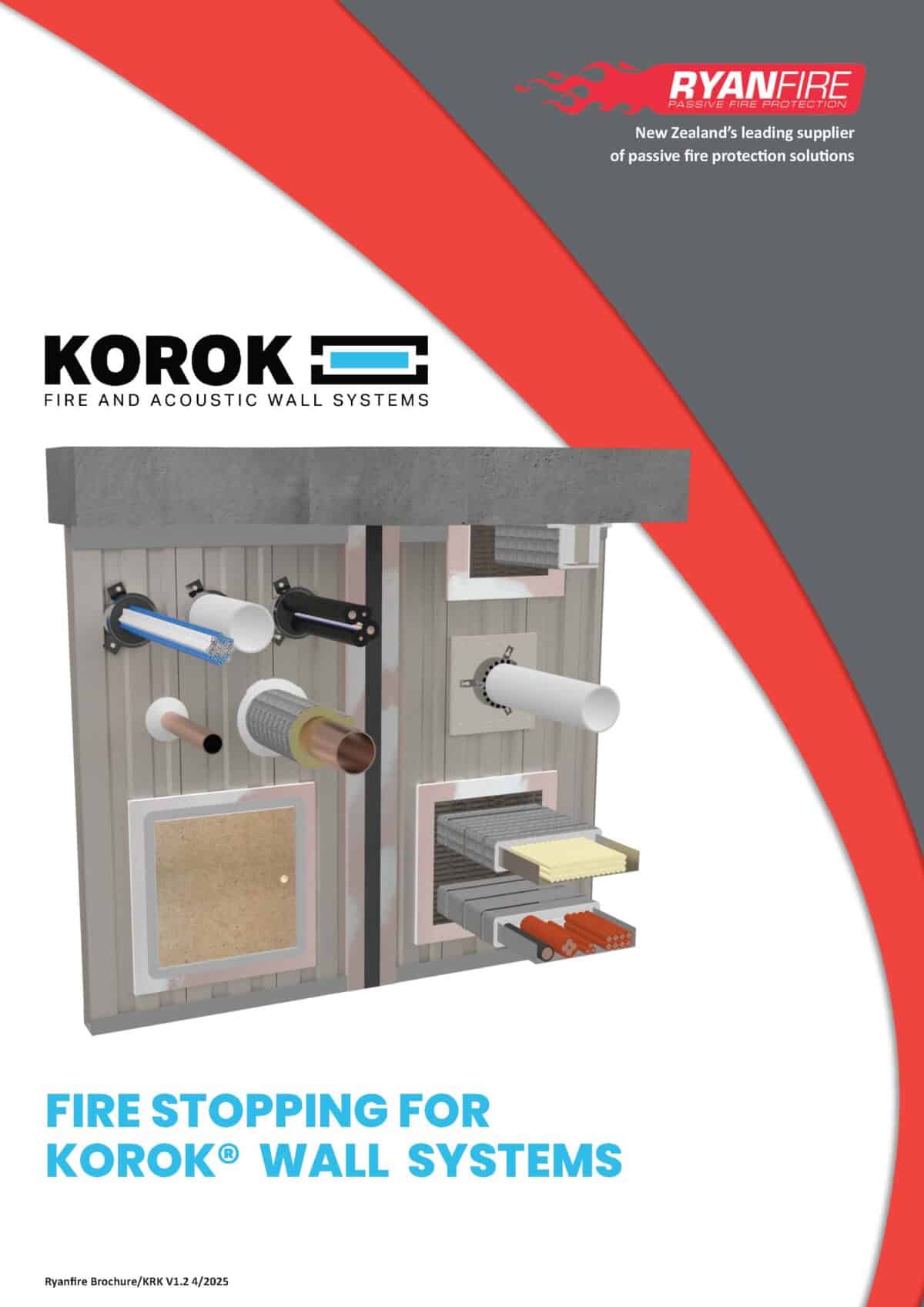

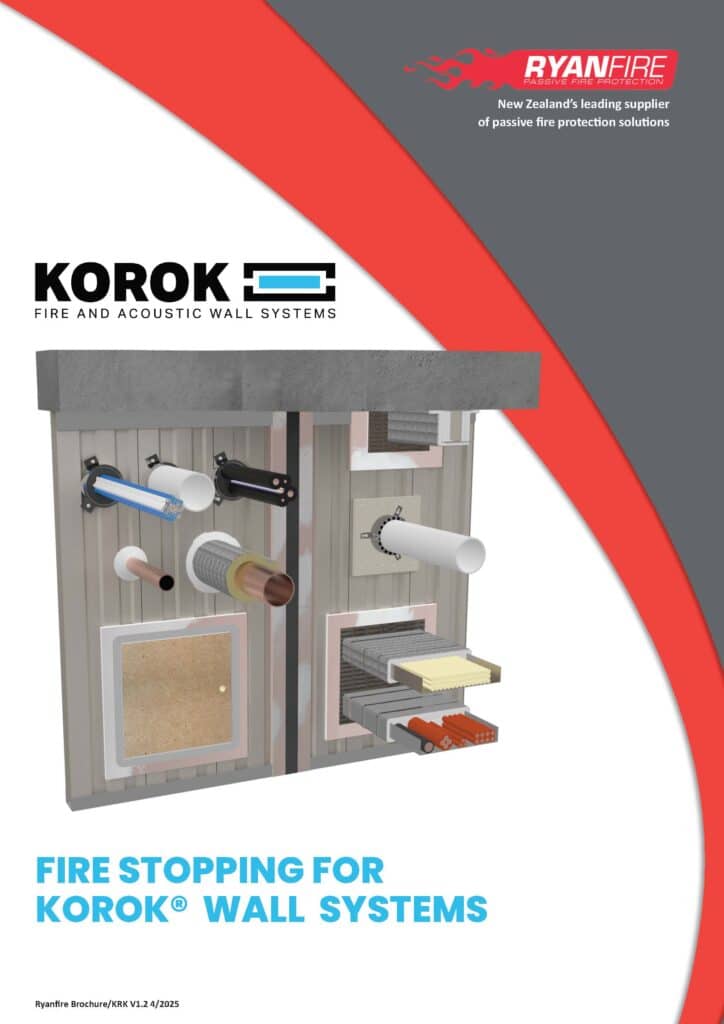

Fire & Acoustic Wall Systems Trusted in Healthcare. KOROK® is a proven fire and acoustic wall system that delivers key performance benefits for healthcare construction. Hospitals demand the highest standards in safety, acoustic control, compliance and speed of delivery. KOROK delivers – with BRANZ-appraised, tested systems that are already trusted in hospitals, corridors, IT rooms, service risers, lift shafts, and more

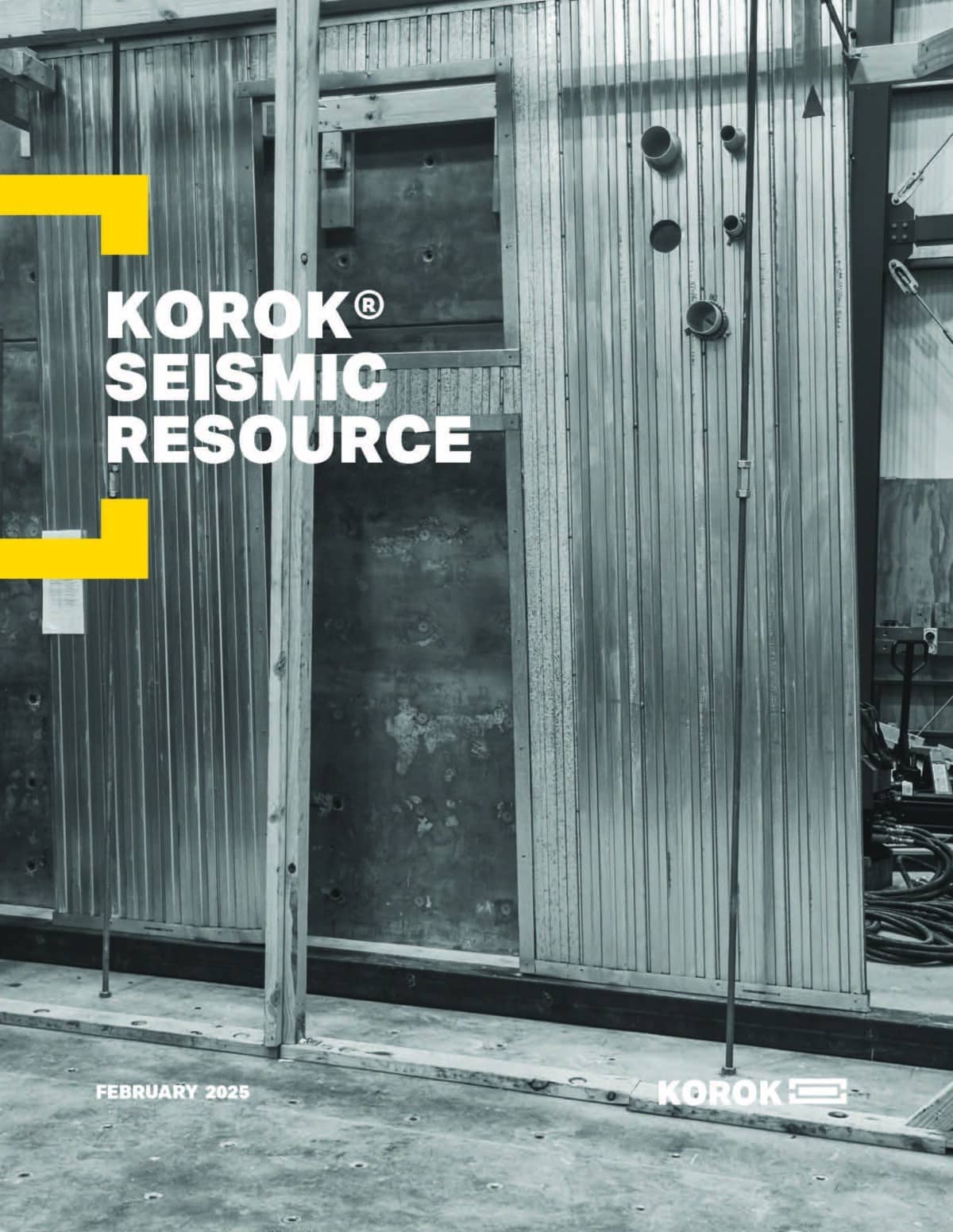

Engineered for IL3/IL4 Resilience: Seismic Performance and Rapid Remediation Design

As the ultimate All-in-One solution for fire & acoustic-rated wall systems, KOROK® panels offer unmatched performance for high-importance structures. With strong seismic performance and the ability to withstand high drift limits, KOROK® panels are ideal for IL3 and IL4 buildings, such as hospitals, emergency response centres, and essential utilities. By undertaking this seismic testing, KOROK® reinforces its commitment to superior building resilience, helping to minimize damage, lower repair costs, and maintain operational continuity after earthquakes.

Core Benefits That Deliver Certainty in Fire, Acoustic, Seismic, and Programme Performance

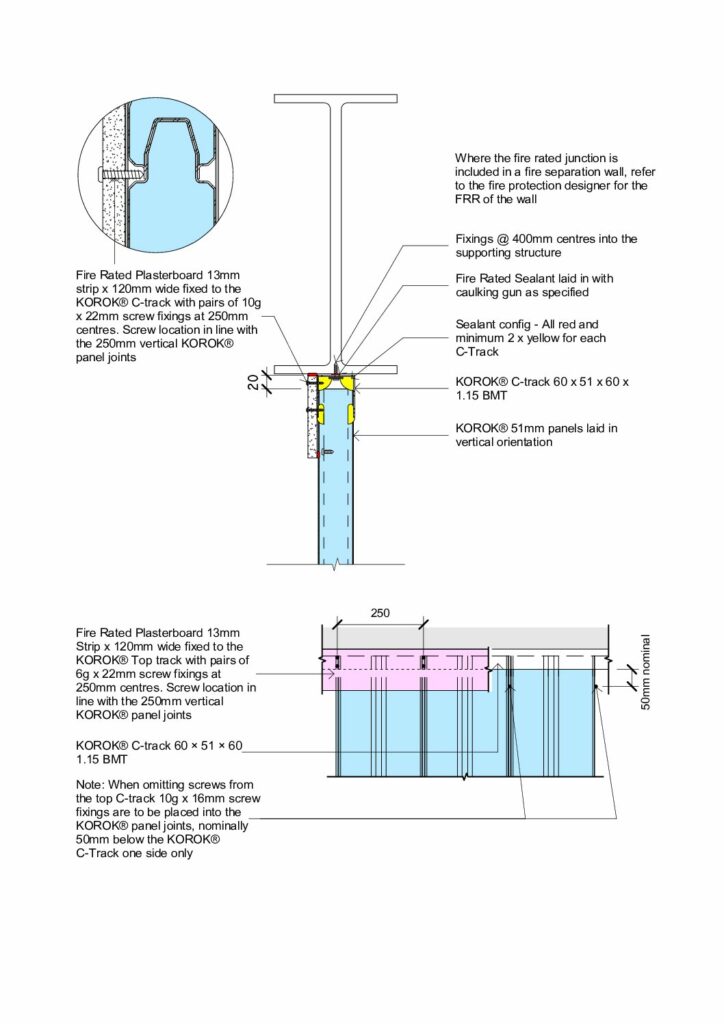

✔ Superior Fire Protection

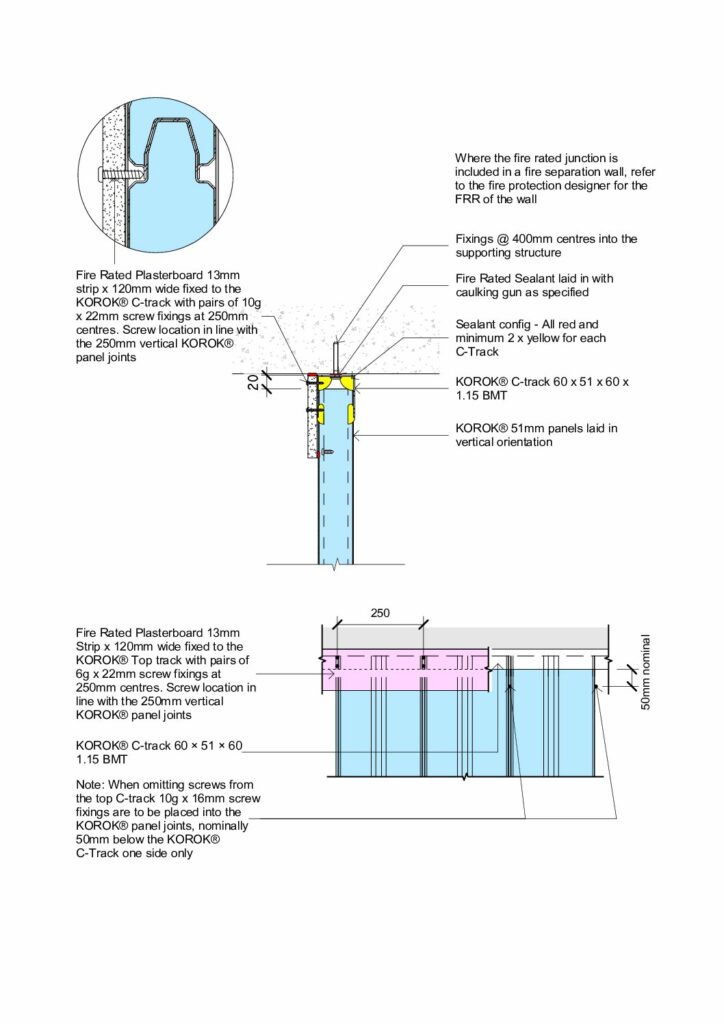

Up to 120-minute FRR (Fire Resistance Ratings) for life-saving passive fire containment.

✔ Acoustic Excellence

Helps achieve compliance with hospital acoustic standards, improving privacy and patient comfort.

✔ Faster Installation

Lightweight, dry-construction modular design = faster program, fewer delays, and earlier handover.

✔ Seismic Resilience

Engineered seismic clips and deflection heads for movement-tolerant, post-event integrity.

All-in-one Solution for all Fire and Acoustic Rated Walls, Engineered for Complex Healthcare Builds

One system, multiple applications. From intertenancy walls to lift shafts, risers, ducts and corridors. KOROK panels provide comprehensive protection throughout your entire project.

LIFT SHAFTS

SERVICE RISERS & DUCTS

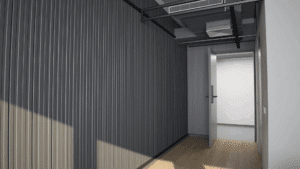

CORRIDORS & HALLWAYS

INTERTENANCY WALLS

STAIRCASE & ESCAPE PATHS

PLANT ROOMS & IT ROOMS

Save Time. Save Labour. Reduce Risk.

For Designers & Specifiers |

For Construction Companies |

|

|

|

Need more info or want to present this to a client? We can help

At KOROK, we know that healthcare projects are high-stakes environments, with no room for delays, compliance issues, or uncertainty. That’s why we offer KOROK 360, a full-circle support package developed to give you confidence from concept to completion. Whether you’re in early-stage design or managing construction on site, KOROK 360 provides targeted, hands-on support tailored to your needs

- Expert Technical Support & Documentation

- Sales & Specification Support

- Estimation & Pricing

- Made-to-Measure, Order Support

- Installation & Training Support

- National Logistics Service

- PowerPoint presentations

- Case studies

Ready to Spec KOROK?

Let’s lock it in, and get your project moving with tested, proven performance. Whether you’re working on early-stage design, refining your specification, or needing trusted fire and acoustic systems that meet healthcare demands – we’re here to help. Get expert guidance, fast documentation, and the confidence that comes from working with systems already trusted in hospitals across New Zealand.

Talk to us today and bring KOROK certainty to your next healthcare build.

At

At