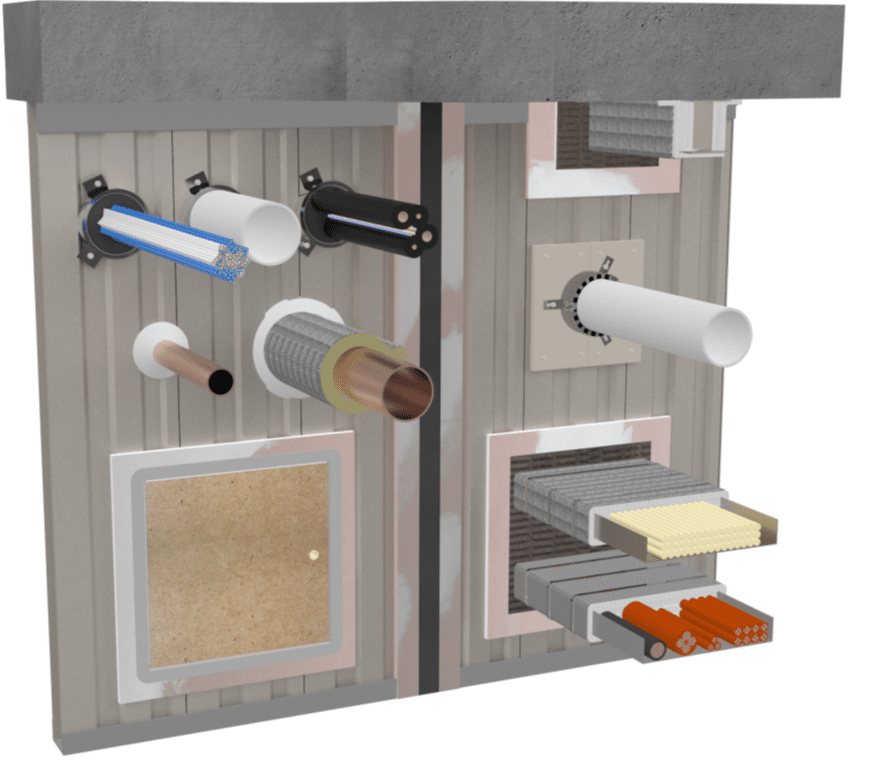

KOROK® Passive Fire Penetrations

When it comes to passive fire penetrations, KOROK® leads the way with innovative solutions that ensure fire safety without compromising functionality.

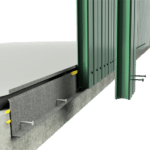

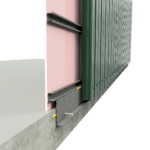

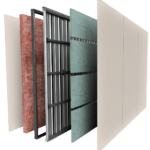

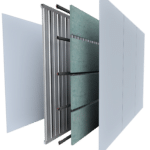

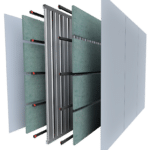

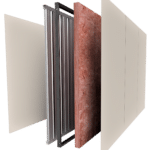

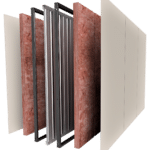

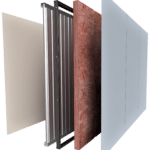

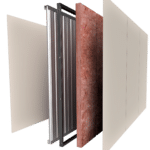

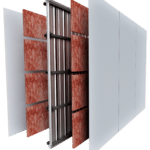

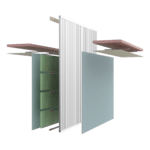

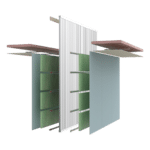

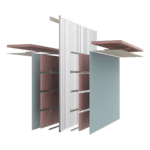

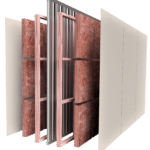

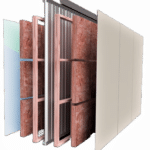

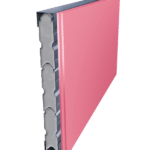

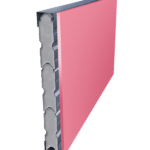

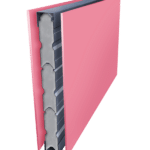

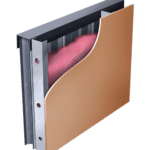

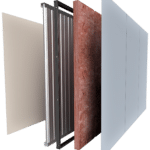

At KOROK®, we are committed to providing fire-rated wall systems that prioritize safety, durability, and performance. Our advanced KOROK® panels are specifically designed to allow seamless integration of passive fire penetrations, including service ducting and pipes, while maintaining the structural and fire integrity of the wall.

What Are Passive Fire Penetrations?

Passive fire penetrations are openings or pathways in fire-rated walls or floors that allow services such as plumbing, electrical cables, or ductwork to pass through. These penetrations are essential for building functionality but must be carefully designed to prevent the spread of fire and smoke. KOROK® panels are engineered to make the creation and sealing of these penetrations straightforward and effective, ensuring compliance with strict fire safety standards.

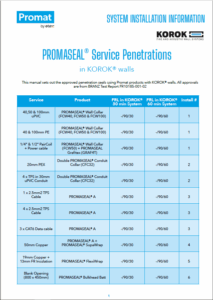

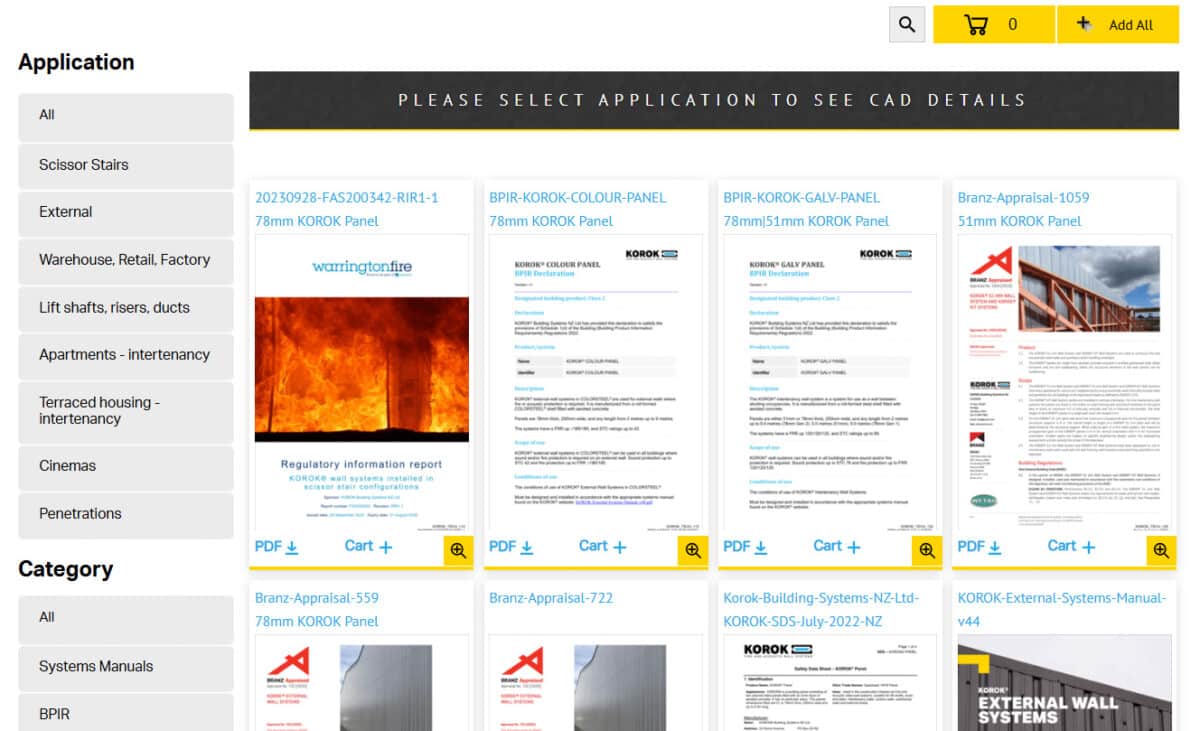

Fire Stopping Guidance Documents

At KOROK®, we understand that ensuring fire safety goes beyond the wall system itself – it’s also about how penetrations and services are detailed. That’s why we’ve collaborated with leading experts in passive fire protection to develop a suite of manuals that provide fully tested, NZBC-compliant solutions for penetrations in KOROK® fire-rated wall systems.

Each manual has been developed in partnership with industry specialists and contains tested configurations, installation guidance, and compliance references, making it easier for designers, engineers, and contractors to select the right firestop solutions.

Our firestop manuals, developed with industry partners, provide tested and NZBC-compliant solutions for service penetrations in KOROK® fire-rated wall systems.

Why Choose KOROK® for Passive Fire Penetrations?

- Easy Formations for Penetrations: KOROK® panels simplify the creation of openings for ducting and plumbing. The lightweight yet robust design makes it easy to form precise and efficient penetrations without compromising fire safety or wall integrity.

- Maintained Wall Integrity: Even with multiple passive fire penetrations, KOROK® panels ensure the overall wall system retains its fire rating. This is crucial for preventing fire and smoke from spreading across compartments in a building.

- Versatile Applications: Whether your project involves commercial spaces, residential apartments, or industrial facilities, KOROK® passive fire penetrations provide a reliable and efficient solution tailored to meet your needs.

- Compliance with Building Codes: KOROK® panels are rigorously tested and meet or exceed New Zealand’s building code requirements for passive fire protection. This gives architects, engineers, and builders confidence in the safety and performance of their projects.

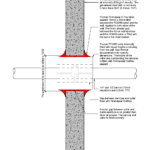

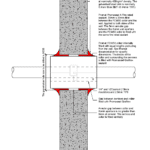

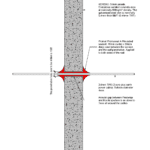

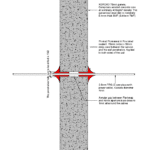

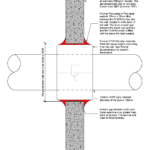

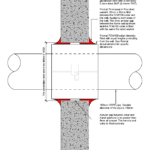

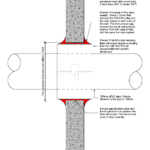

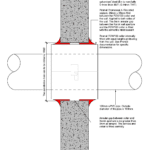

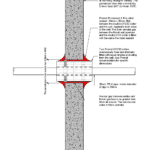

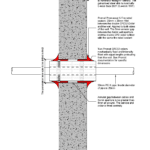

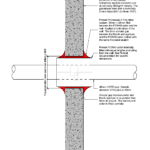

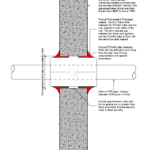

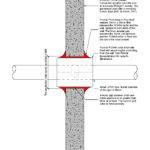

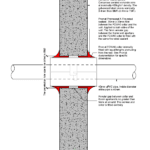

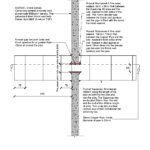

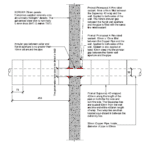

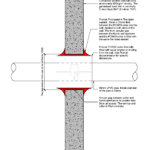

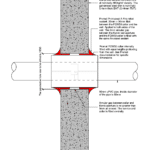

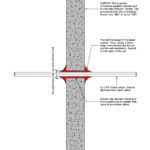

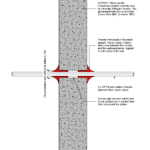

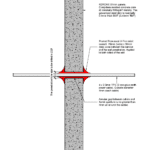

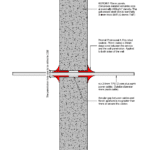

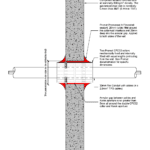

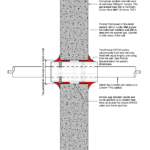

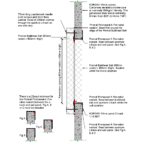

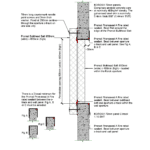

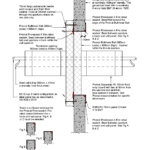

Service Penetrations – KOROK® 51mm & 78mm Panel

| MANUFACTURER | PENETRATION DESCRIPTION | SIZE | SUBTYPE | SYSTEM | FRR | 51MM PANEL DRAWING | 78MM PANEL DRAWING |

|---|---|---|---|---|---|---|---|

| Promat | ¼” & ½” PE insulated pair coil and power cable | Cable | FCW50 | -/90/60 |  <a <a |  <a <a |

|

| Promat | 1 of 2.5 mm² TPS cable | 2.5mm | Cable | Promaseal A Sealant | -/90/60 |  <a <a |  <a <a |

| Promat | 100 mm PE pipe | 100mm | PE / PEX | FCW100 | -/90/60 |  <a <a |  <a <a |

| Promat | 100 mm uPVC pipe | 100mm | uPVC | FCW100 | -/90/60 |  <a <a |  <a <a |

| Promat | 19 mm copper pipe with 13 mm Armaflex insulation | 19mm | Copper pipe | Flexiwrap | -/90/30 | ||

| Promat | 20 mm PEX | 20mm | PE / PEX | CFC32 | -/90/60 |  <a <a |  <a <a |

| Promat | 40 mm PE pipe | 40mm | PE / PEX | FCW40 | -/90/60 |  <a <a |  <a <a |

| Promat | 40 mm uPVC pipe | 40mm | uPVC | FCW40 | -/90/60 |  <a <a |  <a <a |

| Promat | 50 mm copper pipe | 50mm | Copper pipe | Supawrap 40 | -/90/60 |  <a <a |  <a <a |

| Promat | 50 mm uPVC pipe | 50mm | uPVC | FCW50 | -/90/60 |  <a <a |  <a <a |

| Promat | Up to 3 of CAT6 data cables | Cable | Promaseal A Sealant | -/90/60 |  <a <a |  <a <a |

|

| Promat | Up to 4 of 2.5 mm² TPS cables | Cable | Promaseal A Sealant | -/90/60 |  <a <a |  <a <a |

|

| Promat | Up to 4 x 2.5 mm² TPS cable in a 30 mm flexible uPVC conduit | uPVC, Cable | Double CFC32 | -/90/60 |  <a <a |  <a <a |

|

| Promat | Up to 800mm x 400mm (0.32m²) opening | Opening | Promat double bulkhead | -/90/60 |  <a <a |  <a <a |

|

| Promat | Up to 800mm x 400mm (0.32m²) opening with continuous cable tray | Cable | Promat double bulkhead | -/90/60 |  <a <a |  <a <a |

|

| Ryanfire | 150 mm uPVC pipe | 150mm | uPVC | 2 of Ryanfire SL160 collars | -/90/60 | ||

| Ryanfire | 50 mm uPVC pipe | 50mm | uPVC | 2 of Ryanfire SL55 collars | -/90/60 | ||

| Ryanfire | A combination of up to 3 of 3/8” & 3/4” PE insulated pair coil + 6 of 2.5 mm² TPS cables + 25mm diameter uPVC conduit | uPVC, Cable | 2 of Ryanfire SL110 collars | -/90/30 | |||

| Ryanfire | A combination of up to 30 of 2.5mm² TPS cables + 25 of CAT6 cables + 10 of 50pr telecommunications cables | Cable | 2 of Ryanfire SL110 collars | -/90/60 | |||

| Ryanfire | Up to 700mm x 400mm (0.28m²) opening | Opening | Ryanfire double Firetherm Intubatt | -/90/60 | |||

| Holyoake |  |

||||||

| Holyoake |  |

||||||

| Hilti | 1 of Multi-Core Copper Cables PVC/PVC & XLPE/PVC (sheath/insulation) circular or flat 2C+E or 3C+E up to 25mm2 ≤ 23mm Dia. Refer to page 11 | Max. 23mm | Cable | CP611a / CFS-IS Intumescent Sealant | -/120/60 |  |  |

| Hilti | 1 of Multi-Core Copper Cables PVC/PVC & XLPE/PVC (sheath/insulation) circular or flat 2C+E or 3C+E up to 25mm2 ≤ 23mm Dia. Refer to page 12 | Max. 23mm | Cable | CP611a / CFS-IS Intumescent Sealant + 13mm Plasterboard Patch | -/120/90 |  |

|

| Hilti | 1 of single core copper cable PVC/PVC & XLPE/PVC (sheath/insulation) circular cables up to 25mm2 ≤ 10mm Dia. Refer to page 11 | Max. 10mm | Cable | CP611a / CFS-IS Intumescent Sealant | -/120/90 |  |  |

| Hilti | 1 of single core copper cable PVC/PVC & XLPE/PVC (sheath/insulation) circular cables up to 25mm2 ≤ 10mm Dia. Refer to page 12 | Max. 10mm | Cable | CP611a / CFS-IS Intumescent Sealant + 13mm Plasterboard Patch | -/120/120 |  |

|

| Hilti | 1 of Telecommunication cables, Cat5/6/7/8, RG6 Coax Cables & Fiber Optic cables. Refer to page 11 | Cable | CP611a / CFS-IS Intumescent Sealant | -/120/90 |  |  |

|

| Hilti | 1 of Telecommunication cables, Cat5/6/7/8, RG6 Coax Cables & Fiber Optic cables. Refer to page 12 | Cable | CP611a / CFS-IS Intumescent Sealant + 13mm Plasterboard Patch | -/120/120 |  |

||

| Hilti | 110mm ND uPVC-SC Pipe . Refer to pages 28-30 | 110mm | uPVC | CFS-C P 110/4" Fire Collar+ CP606 Acrylic Sealant | -/120/60 |  |  |

| Hilti | 110mm ND uPVC-SC Pipe . Refer to pages 28-30 | 110mm | uPVC | CFS-C P 110/4" Fire Collar+ CP606 Acrylic Sealant + 13mm Plasterboard Patch | -/120/90 |  |

|

| Hilti | 150mm ND uPVC-SC Pipe . Refer to pages 28-30 | 150mm | uPVC | CFS-C P 160/6" Fire Collar+ CP606 Acrylic Sealant | -/120/60 |  |  |

| Hilti | 150mm ND uPVC-SC Pipe . Refer to pages 28-30 | 150mm | uPVC | CFS-C P 160/6" Fire Collar+ CP606 Acrylic Sealant + 13mm Plasterboard Patch | -/120/90 |  |

|

| Hilti | 16 - 200mm Dia. Copper, Ferrous (Steel, Stainless Steel, Iron) or Brass Pipe with Mineral Stone Wool Insulation. Refer to pages 34-37 | Max. 200mm | Batts | CP606 Acrylic Sealant + 1 x 13mm Plasterboard Patch + Mineral Wool Pipe Sleeve (Fibertex 450) 600mm in length | -/120/30 |  | |

| Hilti | 16 - 200mm Dia. Copper, Ferrous (Steel, Stainless Steel, Iron) or Brass Pipe with Mineral Stone Wool Insulation. Refer to pages 34-37 | Max. 200mm | Batts | CP606 Acrylic Sealant + 1 x 13mm Plasterboard Patch + Mineral Wool Pipe Sleeve (Fibertex 450) 600mm in length | -/120/60 |  |

|

| Hilti | 16 - 200mm Dia. Copper, Ferrous (Steel, Stainless Steel, Iron) or Brass Pipe with Mineral Stone Wool Insulation. Refer to pages 34-37 | Max. 200mm | Batts | CP606 Acrylic Sealant + 1 x 13mm Plasterboard Patch + Mineral Wool Pipe Sleeve (Fibertex 450) 600mm in length | -/120/90 |  |

|

| Hilti | 16 - 200mm Dia. Copper, Ferrous (Steel, Stainless Steel, Iron) or Brass Pipe. Refer to pages 34-37 | Max. 200mm | Sealant | CP606 Acrylic Sealant | -/120/- |  |  |

| Hilti | 16 to 32mm Dia. uPVC Rigid conduit filled with Cables, Fiber Optics or mixture of both. Refer to pages 15-17 | Max. 32mm | uPVC, Cable | CFS-C P 50/1.5" Fire Collar + CP606 Acrylic Sealant + CP611a / CFS-IS Intumescent Sealant + 13mm Plasterboard Patch | -/120/90 |  |

|

| Hilti | 16 to 50mm Dia. uPVC Rigid conduit (Empty). Refer to pages 15-16 | Max. 50mm | uPVC | CFS-C P 50/1.5" Fire Collar + CP606 Acrylic Sealant + CP611a / CFS-IS Intumescent Sealant | -/120/60 |  |  |

| Hilti | 16 to 50mm Dia. uPVC Rigid conduit (Empty). Refer to pages 15-17 | Max. 50mm | uPVC | CFS-C P 50/1.5" Fire Collar + CP606 Acrylic Sealant + CP611a / CFS-IS Intumescent Sealant + 13mm Plasterboard Patch | -/120/90 |  |

|

| Hilti | 16 to 50mm Dia. uPVC Rigid conduit filled with Cables, Fiber Optics or mixture of both. Refer to pages 15-16 | Max. 50mm | uPVC, Cable | CFS-C P 50/1.5" Fire Collar + CP606 Acrylic Sealant + CP611a / CFS-IS Intumescent Sealant | -/120/60 |  |  |

| Hilti | 16mm Dia. PE-X/AL/PE or PE-Xb/AL/PE-Xb. Refer to pages 31-33 | 16mm | PE / PEX | CP611a / CFS-IS Intumescent Sealant + 13mm Plasterboard Patch & Sealant Cone | -/120/90 |  |

|

| Hilti | 16mm Dia. PE-X/AL/PE. Refer to pages 31-32 | 16mm | PE / PEX | CP611a / CFS-IS Intumescent Sealant | -/120/60 |  |  |

| Hilti | 16mm Dia. PE-Xa or PE-Xb. Refer to pages 31-33 | 16mm | PE / PEX | CP611a / CFS-IS Intumescent Sealant + 13mm Plasterboard Patch & Sealant Cone | -/120/120 |  |

|

| Hilti | 16mm Dia. PE-Xa. Refer to pages 31-32 | 16mm | PE / PEX | CP611a / CFS-IS Intumescent Sealant | -/120/90 |  |  |

| Hilti | 20 & 25mm Dia. PP Flexible conduit (Empty). Refer to pages 18-19 | Max. 25mm | CFS-C P 50/1.5" Fire Collar + CP606 Acrylic Sealant + CP611a / CFS-IS Intumescent Sealant | -/120/- |  |  |

|

| Hilti | 20 & 25mm Dia. PP Flexible conduit filled with Cables, Fiber Optics or mixture of both. Refer to pages 18-19 | Max. 25mm | Cable | CFS-C P 50/1.5" Fire Collar + CP606 Acrylic Sealant + CP611a / CFS-IS Intumescent Sealant | -/120/60 |  |  |

| Hilti | 20 & 25mm Dia. PP Flexible conduit filled with Cables, Fiber Optics or mixture of both. Refer to pages 18-20 | Max. 25mm | Cable | CFS-C P 50/1.5" Fire Collar + CP606 Acrylic Sealant + CP611a / CFS-IS Intumescent Sealant + 13mm Plasterboard Patch | -/120/90 |  |

|

| Hilti | 20 to 50mm Dia. uPVC Flexible conduit (Empty). Refer to pages 18-19 | Max. 50mm | uPVC | CFS-C P 50/1.5" Fire Collar + CP606 Acrylic Sealant + CP611a / CFS-IS Intumescent Sealant | -/120/- |  |  |

| Hilti | 20 to 50mm Dia. uPVC Flexible conduit filled with Cables, Fiber Optics or mixture of both. Refer to pages 18-19 | Max. 50mm | uPVC, Cable | CFS-C P 50/1.5" Fire Collar + CP606 Acrylic Sealant + CP611a / CFS-IS Intumescent Sealant | -/120/90 |  |  |

| Hilti | 20 to 50mm Dia. uPVC Flexible conduit filled with Cables, Fiber Optics or mixture of both. Refer to pages 18-20 | Max. 50mm | uPVC, Cable | CFS-C P 50/1.5" Fire Collar + CP606 Acrylic Sealant + CP611a / CFS-IS Intumescent Sealant + 13mm Plasterboard Patch | -/120/120 |  |

|

| Hilti | 20mm Dia. PE-X/AL/PE or PE-Xb/AL/PE-Xb. Refer to pages 31-33 | 20mm | CP611a / CFS-IS Intumescent Sealant + 13mm Plasterboard Patch & Sealant Cone | -/120/90 |  |

||

| Hilti | 20mm Dia. PE-X/AL/PE. Refer to pages 31-32 | 20mm | CP611a / CFS-IS Intumescent Sealant | -/120/60 |  |  |

|

| Hilti | 20mm Dia. PE-Xa or PE-Xb. Refer to pages 31-33 | 20mm | CP611a / CFS-IS Intumescent Sealant + 13mm Plasterboard Patch & Sealant Cone | -/120/120 |  |

||

| Hilti | 20mm Dia. PE-Xa. Refer to pages 31-32 | 20mm | CP611a / CFS-IS Intumescent Sealant | -/120/90 |  |  |

|

| Hilti | 25mm Dia. PE-X/AL/PE or PE-Xb/AL/PE-Xb. Refer to pages 31-33 | 25mm | CP611a / CFS-IS Intumescent Sealant + 13mm Plasterboard Patch & Sealant Cone | -/120/90 |  |

||

| Hilti | 25mm Dia. PE-X/AL/PE. Refer to pages 31-32 | 25mm | CP611a / CFS-IS Intumescent Sealant | -/120/60 |  |  |

|

| Hilti | 25mm Dia. PE-Xa or PE-Xb. Refer to pages 31-33 | 25mm | CP611a / CFS-IS Intumescent Sealant + 13mm Plasterboard Patch & Sealant Cone | -/120/120 |  |

||

| Hilti | 25mm Dia. PE-Xa. Refer to pages 31-32 | 25mm | CP611a / CFS-IS Intumescent Sealant | -/120/90 |  |  |

|

| Hilti | 32mm Dia. PE-X/AL/PE. Refer to pages 31-32 | 32mm | CP611a / CFS-IS Intumescent Sealant | -/120/60 |  |  |

|

| Hilti | 32mm Dia. PE-X/AL/PE. Refer to pages 31-33 | 32mm | CP611a / CFS-IS Intumescent Sealant + 13mm Plasterboard Patch & Sealant Cone | -/120/90 |  |

||

| Hilti | 40mm ND uPVC Pipe. Refer to pages 28-30 | 40mm | uPVC | CFS-C P 50/1.5" Fire Collar + CP606 Acrylic Sealant | -/120/60 |  |  |

| Hilti | 40mm ND uPVC Pipe. Refer to pages 28-30 | 40mm | uPVC | CFS-C P 50/1.5" Fire Collar + CP606 Acrylic Sealant + 13mm Plasterboard Patch | -/120/90 |  |

|

| Hilti | 50mm ND uPVC Pipe. Refer to pages 28-30 | 50mm | uPVC | CFS-C P 63/2.0" Fire Collar + CP606 Acrylic Sealant | -/120/90 |  |  |

| Hilti | 50mm ND uPVC Pipe. Refer to pages 28-30 | 50mm | uPVC | CFS-C P 63/2.0" Fire Collar + CP606 Acrylic Sealant + 13mm Plasterboard Patch | -/120/120 |  |

|

| Hilti | 65mm ND uPVC Pipe. Refer to pages 28-30 | 65mm | uPVC | CFS-C P 75/2.5" Fire Collar + CP606 Acrylic Sealant | -/120/90 |  |  |

| Hilti | 65mm ND uPVC Pipe. Refer to pages 28-30 | 65mm | uPVC | CFS-C P 75/2.5" Fire Collar + CP606 Acrylic Sealant + 13mm Plasterboard Patch | -/120/120 |  |

|

| Hilti | 80mm ND uPVC Pipe. Refer to pages 28-30 | 80mm | uPVC | CFS-C P 90/3" Fire Collar + CP606 Acrylic Sealant | -/120/90 |  |  |

| Hilti | 80mm ND uPVC Pipe. Refer to pages 28-30 | 80mm | uPVC | CFS-C P 90/3" Fire Collar + CP606 Acrylic Sealant + 13mm Plasterboard Patch | -/120/120 |  |

|

| Hilti | Cable Bundle ≤ 36mm Dia. Any combination of Telecommunication cables, Cat5/6/7/8, Fiber Optic cables,RG6 Quad Shield Coax or TPS 2C+E up to 2.5mm2. Refer to pages 13-14 | Max. 36mm | Cable | CP611a / CFS-IS Intumescent Sealant | -/120/60 |  |  |

| Hilti | Cable Bundle ≤ 36mm Dia. Any combination of Telecommunication cables, Cat5/6/7/8, Fiber Optic cables,RG6 Quad Shield Coax or TPS 2C+E up to 2.5mm2. Refer to pages 13-14 | Max. 36mm | Cable | CP611a / CFS-IS Intumescent Sealant + CFS-P BA Putty Bandage | -/120/90 |  |

|

| Hilti | Cable Tray up to 600mm Wide with 9 x 400mm2 XLPE/PVC or PVC/PVC Sheath/Insulated Single Core Copper or Aluminum Power Cables. Refer to pages 21-27 | Cable | 2 x Layers CP670 Coated Board + CP611a / CFS-IS Intumescent Sealant + CFS-P BA Putty Bandage | -/60/60 |  |  |

|

| Hilti | Cable Tray up to 600mm Wide with AS1530.4 Standard D1 XLPE/PVC or PVC/PVC Sheath/Insulated Power Cables Cable Sets. Refer to pages 21-27 | Cable | 2 x Layers CP670 Coated Board + CP611a / CFS-IS Intumescent Sealant + CFS-P BA Putty Bandage | -/120/90 |  |  |

|

| Hilti | Cable Tray up to 600mm Wide with AS1530.4 Standard D2 Telecommunication Cable Sets. Refer to pages 21-27 | Cable | 2 x Layers CP670 Coated Board + CP611a / CFS-IS Intumescent Sealant + CFS-P BA Putty Bandage | -/90/60 |  |  |

|

| Hilti | Up to 10 of Quad Shield Coax Cables. Refer to pages 13-14 | Cable | CP611a / CFS-IS Intumescent Sealant + CFS-P BA Putty Bandage | -/120/90 |  |

||

| Hilti | Up to 16 of Telecommunication cables, Cat5/6/7/8 & Fiber Optic cables. Refer to pages 13-14 | Cable | CP611a / CFS-IS Intumescent Sealant | -/120/90 |  |  |

|

| Hilti | Up to 16 of Telecommunication cables, Cat5/6/7/8 & Fiber Optic cables. Refer to pages 13-14 | Cable | CP611a / CFS-IS Intumescent Sealant + CFS-P BA Putty Bandage | -/120/120 |  |

||

| Hilti | Up to 8 of TPS 2C+E up to 2.5mm2. Refer to pages 13-14 | CP611a / CFS-IS Intumescent Sealant | -/120/60 |  |  |

||

| Hilti | Up to 8 of TPS 2C+E up to 2.5mm2. Refer to pages 13-14 | CP611a / CFS-IS Intumescent Sealant + CFS-P BA Putty Bandage | -/120/90 |  |