New Fire Barrier Manual for KOROK® Wall Systems

In Partnership with RYANFIRE

We’re excited to share a new resource designed to simplify fire-stopping with KOROK® wall systems.

In collaboration with our trusted partners at RYANFIRE, we’ve released the KOROK® Fire Barrier Manual – your go-to guide for fire-stopping penetrations in KOROK® fire-rated wall systems. 🔥

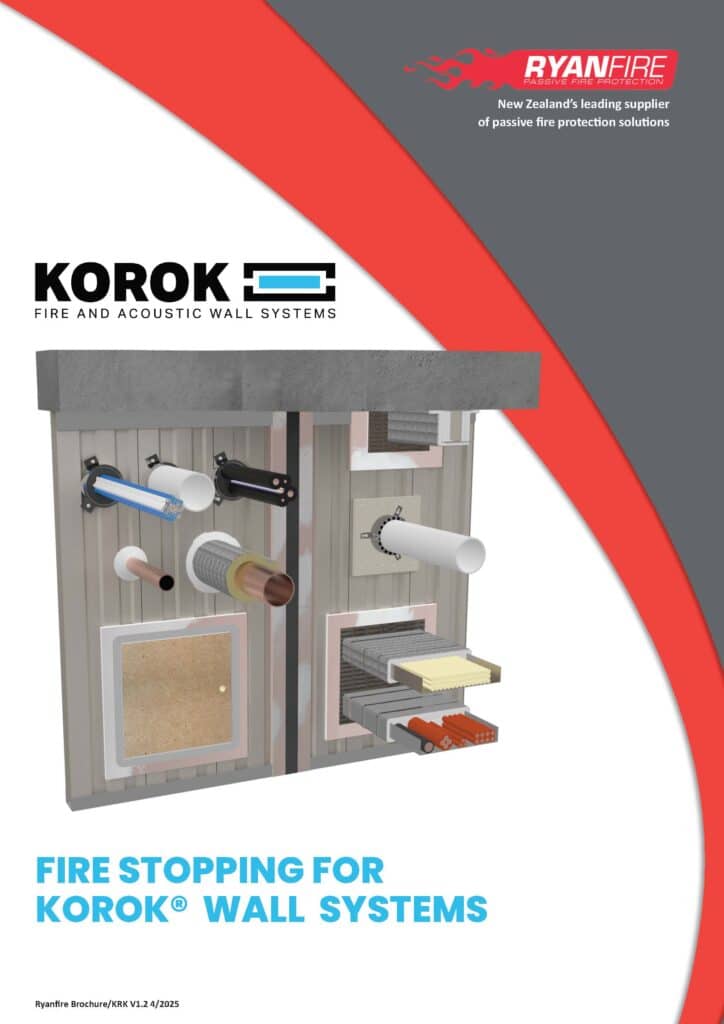

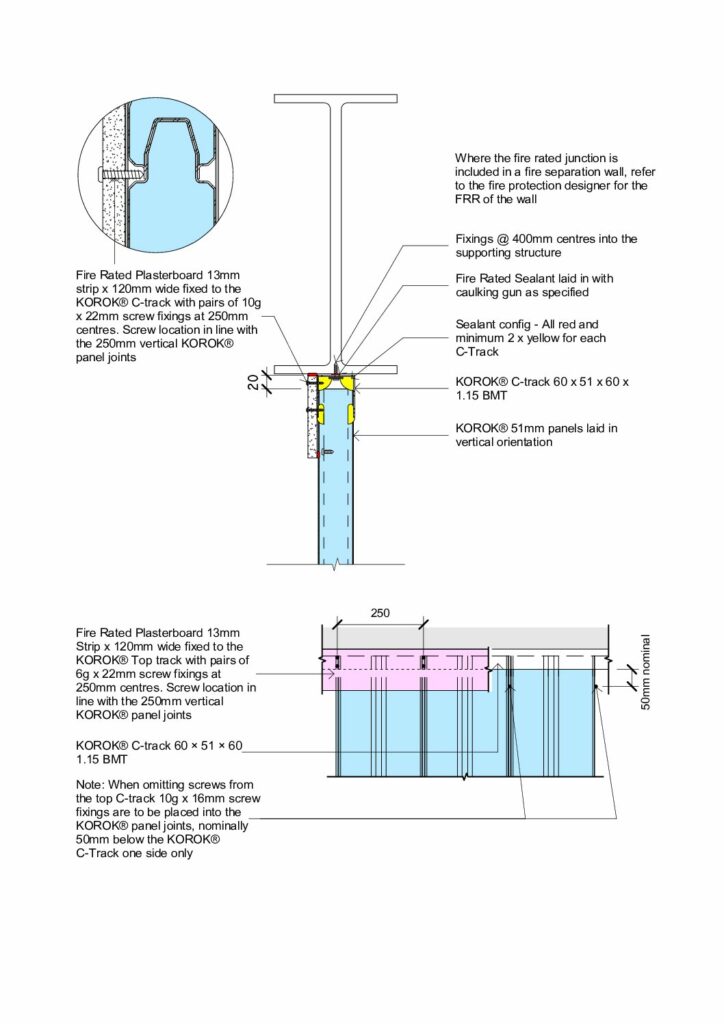

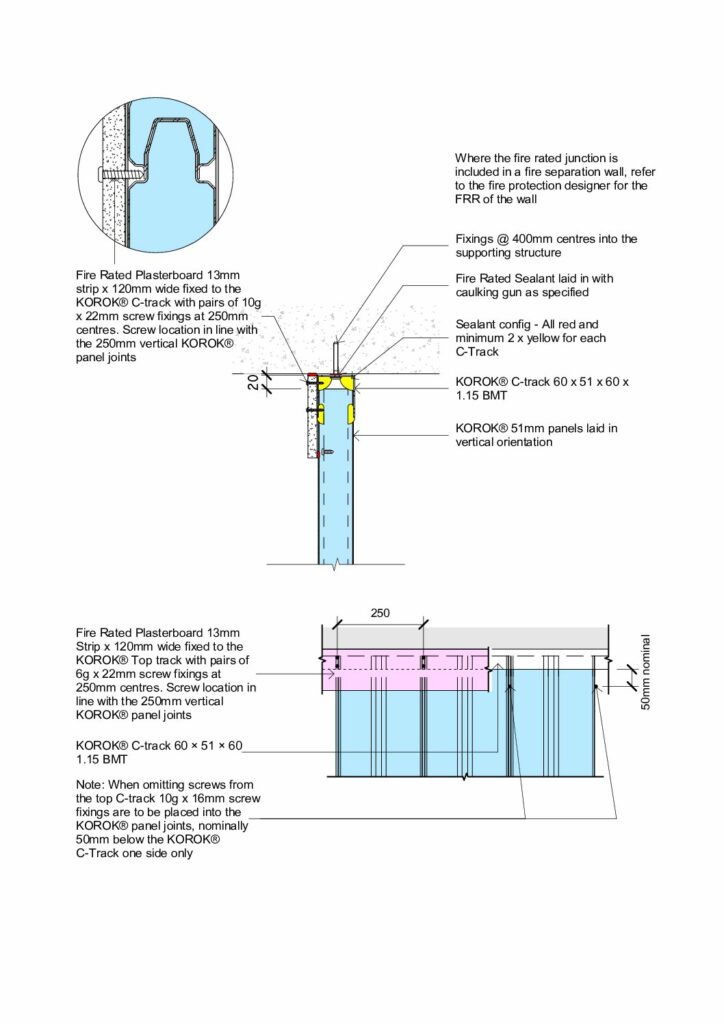

Passive fire penetrations – such as plumbing, electrical, and ductwork openings – play a crucial role in building performance, but they also pose fire risks if not handled correctly. This manual provides fully tested and compliant solutions that meet the latest NZBC requirements, with systems specifically designed and approved for use in KOROK® walls.

What’s inside:

✔️ Tested systems for passive fire penetrations

✔️ NZBC-compliant solutions

✔️ Easy-to-follow installation guidance

✔️ Developed with expert input from RYANFIRE – leaders in passive fire protection

This is just another example of how our longstanding partnership with RYANFIRE is helping deliver smarter, more efficient fire safety on site.

📥 Download the manual now and stay compliant with confidence.