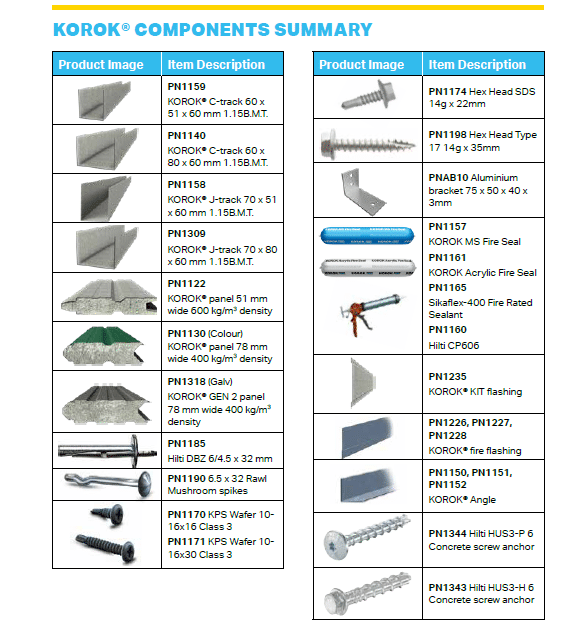

Butt Joints

When Fire Safety Meets Real-World Construction Challenges

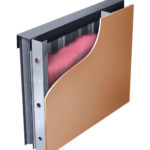

Butt joints – where two panels meet end-to-end. KOROK® provides an engineered approach so your wall performs as designed across 51 mm (60-minute) and 78 mm (120-minute) KOROK panel systems.

Typical on-site scenarios: panels ordered too short, using leftover stock, restricted site access limiting panel length, or panel cuts needed for complex installations.

Applications

- Single-panel butt joint

- Double-panel butt joint

Methods (Butt Joints)

- Profiled cover / steel flat plate – one or both sides, as detailed.

- Back-to-back C-tracks – protected and unprotected variants.

Plugging Circular Holes (≤ Ø160 mm)

For small circular openings created during installation, repairs, or services, use KOROK-tested plug details to maintain system performance.

Methods

- Fire-rated batt plug + steel flat plate

- Fire-rated batt plug + fire-rated batt cover

Refer to the Detail Pack for FRR outcomes, fixing patterns, edge distances, sealant specification, and minimum spacings.

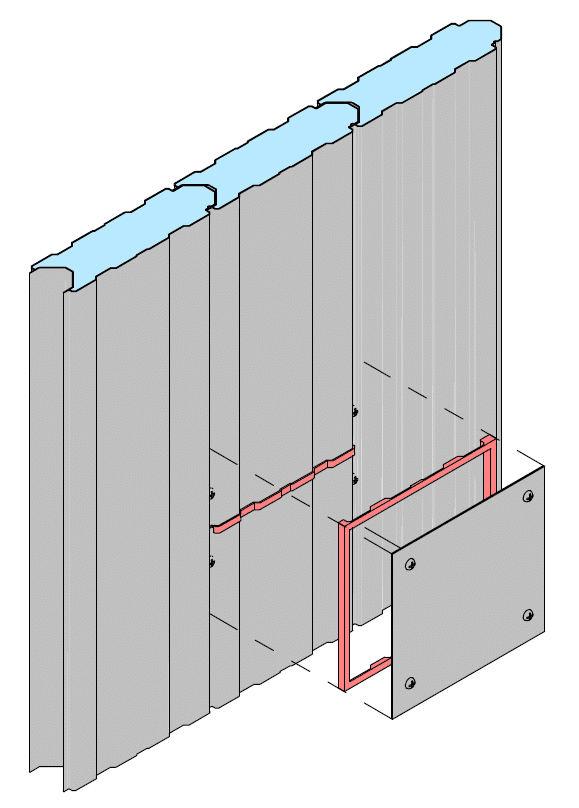

KOROK Access Panel Safe Removal & Reinstallation Procedure

KOROK Access Panel – Safe Removal & Reinstallation Procedure

⚠ WARNING – HEAVY PANEL (33 kg)!

IN ACCORDANCE WITH NEW ZEALAND HEALTH & SAFETY REQUIREMENTS

- 33 kg Weight: This panel is heavy and may cause serious injury if not handled correctly.

- Team Lift Mandatory: Always use at least two people or appropriate mechanical lifting equipment.

- Wear Proper PPE: Use gloves, safety footwear, and any other required personal protective equipment.

- Follow Lifting Procedures: Ensure you follow all site-specific and WorkSafe New Zealand guidelines, including a proper risk assessment before lifting.

- Secure Installation: Confirm that the panel is securely supported during movement and installation.

Failure to use correct lifting methods and PPE may result in severe injury or property damage.

- Applicable Panel Type: Fire-Rated Ceiling Access Panels

- Panel Weight: Approx. 33 kg (Team lift required)

- PPE Required: Gloves, safety boots, hard hat, safety glasses

STEP 1. PREPARATION & SAFETY CHECKS

- Ensure all relevant site safety protocols and WorkSafe NZ guidelines are followed.

- Review the access panel warning label and lifting instructions prior to beginning.

- Conduct a job safety analysis (JSA) or task risk assessment.

- Inspect the work area for overhead hazards and confirm safe clearance for panel lowering.

- Confirm required PPE is worn and in good condition.

- Gather appropriate tools:

- Socket set or spanners

- Mechanical lifting aid (optional but recommended)

- Clean drop cloth or secure storage pallet

STEP 2. SUPPORTING THE PANEL

- Before any bolts are loosened, ensure the panel is securely supported by:

- Two competent personnel (manual lift), or

- An approved mechanical lifting device.

- Support the panel from beneath to prevent any unplanned movement.

STEP 3. BOLT REMOVAL PROCEDURE

- Remove all perimeter bolts, retaining one bolt at each angle line to maintain panel stability.

- Do not remove any screws or TEK-type fasteners that:

- Secure the panel frame to the hatch, or

- Secure support angles to the ceiling C-track structure.

STEP 4. PANEL REMOVAL

- Once weight is fully supported and remaining bolts are accessible, remove the final two bolts.

- Carefully lower the panel straight down, ensuring no twist or torque is applied to the frame.

- Immediately place the panel on a prepared soft surface or pallet to avoid damage.

- Store panel in a secure, dry, and protected area free from impact risk.

STEP 5. CONDITION INSPECTION (PRE-REINSTALLATION)

Perform a full visual and physical inspection of the following components:

- Hatch door surface for warping, dents, or cracks

- Frame integrity including weld points and connection tabs

- Intumescent seal – check for continuous seal and any cracking or displacement

- Promatect® fire board – check for chipping, delamination, or moisture ingress

Replace any damaged or non-compliant components before proceeding with reinstallation.

- REINSTALLATION PROCEDURE

- Position the access panel under the aperture using team lift or lifting device.

- Align the panel with the original bolt holes and insert bolts at each angleline.

- Once Securing nut and bolt assys are secured, reinstall remaining bolts in a crisscross pattern to ensure even loading.

- Torque all fasteners to manufacturer-recommended specification if available.

- Visually verify that the panel is flush with the ceiling and that all mechanical fixings are secured.

Contact our Installation & Technical Support Manager for any questions you may have.

- Daryl Stroebel

- M: 021 193 7609

- E: daryl@korok.com

Seismic Resource

KOROK® Seismic Resource

Setting the Benchmark for Seismic Resilience

KOROK® has set a new benchmark in seismic performance, demonstrating exceptional durability under rigorous in-plane and out-of-plane seismic testing. KOROK Panels have the ability to withstand high levels of drift , ensuring minimal damage, reduced repair costs, and faster recovery after earthquakes.

Leading the Market in Seismic Testing

KOROK® has recently undergone comprehensive seismic testing, setting a new benchmark to support our fire and acoustic wall performance. For over 25 years, we have delivered high-performance solutions across the residential, industrial, and commercial markets.

The Purpose Behind Our Testing

To understand and determine the behavior and performance of KOROK wall panels when subjected to seismic design loads occurring between structural slabs within buildings.

To demonstrate how KOROK® panels respond in correlation with drift levels for both in-plane and out-of-plane conditions, and to support the market with tested solutions. By undertaking this seismic testing, KOROK® reinforces its commitment to superior building resilience, helping to minimize damage, lower repair costs, and maintain operational continuity after earthquakes.

Importance of Seismic Resilience

The 2010/2011 Christchurch earthquakes and the more recent 2013 Lower North Island earthquakes illustrated the vulnerability of building non-structural elements (partitions, building services and piping). Widespread damage and loss of business continuity due to the poor performance of non-structural elements was widely observed

The Canterbury Earthquakes Royal Commission identified the need to improve the performance of non-structural elements in earthquakes with one of the recommendations focussed on improving non-structural element performance. “To prevent or limit the amount of secondary damage, engineers and architects should collaborate to minimise the potential distortion applied to non-structural elements. Particular attention must be paid to prevent the failure of non-structural elements blocking egress routes.”

Proven Seismic Performance

Conducted at BRANZ in 2024, our seismic tests followed FEMA 461 and NZS 1170.5:2004 standards, confirming KOROK® panels has the ability to withstand high levels of drift. No other system in New Zealand has undergone such rigorous testing with multiple wall configurations and variations.

Application in High-Importance Structures

As the ultimate All-in-One solution for fire & acoustic-rated wall systems, KOROK® panels offer unmatched performance for high-importance structures. With strong seismic performance and the ability to withstand high drift limits, KOROK® panels are ideal for IL3 and IL4 buildings, such as hospitals, emergency response centres, and essential utilities. KOROK® provides stakeholders, architects, and engineers with confidence in a durable, high-performance solutions.

Test Video of Typical Wall Configuration

In Plane 78mm KOROK® with head track fixing. Vertical panel installation with no apertures.

In-plane loading of 78mm KOROK® with head track fixing. Vertical panel installation with apertures.

Out of plane loading of 78mm KOROK® with head track fixing. Vertical panel installation with apertures.

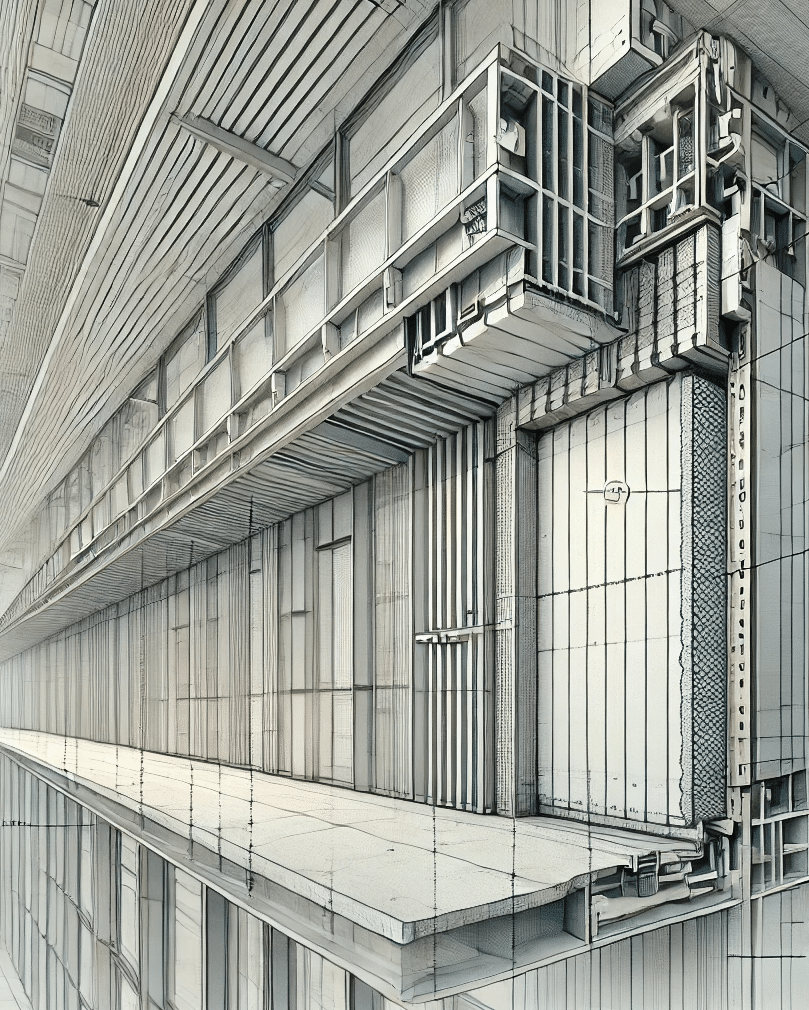

Panel Handling

When discussing construction techniques, one important aspect to consider is panel handling, which ensures safety and efficiency on site.

Panel Handling

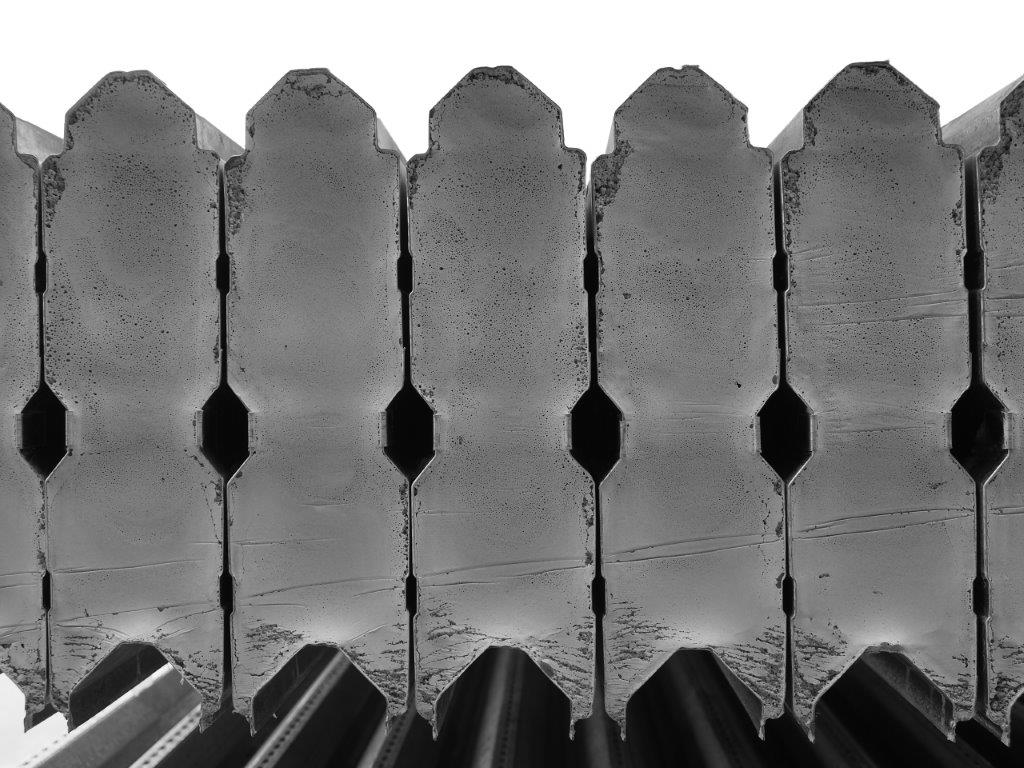

KOROK manufactures lightweight wall panels consisting of galvanised or colour steel shells filled with aerated concrete.

Generally, KOROK products are delivered to your building or other site on long trailers and articulated trucks.

Our products are packed with reasonable protection against damage during delivery, however care must be exercised during unloading.

Forklift, Hiab or crane unload is required.

GUIDELINES

Ensure packs are lifted slowly, avoiding jerking where possible.

Forklift unloading – 150mm between pack and mast.

Ensure soft slings are neatly running on the inside of the two most inner timber collars of the pack.

Ensure soft slings are running continuously from the hooks to underneath the pack and back up to the hook.

Do not loop the sling around itself with only one end connected to the hook. This may damage the panels when lifted.

Ensure you lift only one or two packs at a time.

PACK SIZES

The panels are packed in timber pallets, measuring 1200mm wide by 300mm high.

There will be 2, 4 or 6 timber pallets for each pack (depending on length), nominally spaced 1200mm apart, middled from pack centre.

Packs can be stacked up to 6 packs high and must be placed side by side or end on end, on the truck / trailer tray.

When stacking back-to-back, timber collars must butt up against each other.

The length of the pack will vary according to the length of the panel required by the customer, commonly between 2.0 and 7.0 metres in length (can be up to 9.0m).

COMMON PACK WEIGHTS

Standard 3 metre pack = 390 – 470kg (nominal); Standard 6 metre pack = 780 – 936kg (nominal).

STRAPPING DOWN PACKS

Loads must be strapped down and secured by appropriate means. Load strops are most highly recommended, allowing 12 to 16 strops for a full semi load, more for B-Train transport.

Packs are to always be strapped over timber collars. No belly straps done with plastic angles at any time.

When stacking higher than 4 packs, a second set of straps must be placed after the third pack over timber collars only, before adding further packs.

ACCESSORIES

At times, a bundle of steel C-track or Angle strips may be placed on top of the load. These may measure up to 6.0 metres in length and weigh from 10kg to 500kg depending on the quantity.

IN TRANSIT

Where possible, avoid sudden braking and jolts during transit to reduce impacts on the product.

Re-tension strops every two hours at a minimum.

UNLOADING

Forklift, Hiab or crane unload is required.

Use soft slings or forks only, no chains to be used on product.

All lifting to only be done under middle crate, closest to the bearers to take the weight.

Forklift unloading – 150mm between pack and mast.

Care must be taken on unload and storage of product, avoiding bumps and scratching.

Guidelines must be carefully followed (turn over page).

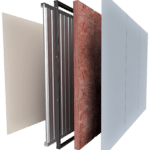

Noise Control Systems

KOROK Noise Control Systems – Additional Acoustic Solutions

Advanced Noise Control Solutions for Targeted Acoustic Performance

KOROK Building Systems introduces additional Acoustic solutions designed to tackle specific sound challenges in modern construction. Originally driven by the unique requirements of cinemas and terraced housing, these solutions bring versatile applications to a wide range of environments, enhancing comfort, privacy, and overall sound quality.

How Noise Control Systems Work

Our systems use a blend of wall densities and build-ups that are tailored to meet the specific acoustic needs of each project. By combining technical insights with flexible design, we provide solutions that integrate seamlessly into diverse building types while maintaining industry-leading standards in acoustic performance.

Key Applications of Noise Control Systems

- Cinemas: Create immersive audio experiences without disruptive sound bleed between theaters, ensuring each audience enjoys undisturbed sound quality.

- Terraced and Multi-Unit Housing: Reduce noise transfer between units to give residents a quieter, more comfortable living environment.

- Other Specialized Spaces: Whether it’s office environments, hospitality spaces, or other commercial projects, our Noise Control Systems improve sound management, making shared and private spaces more acoustically efficient.

Why Choose KOROK Noise Control Systems?

Our additional acoustic solutions were developed with a focus on solving specialized acoustic issues. By studying the effects of various wall densities and configurations, we’ve created adaptable systems that address distinct sound transmission concerns. From minimizing sound bleed in high-traffic areas to achieving optimal acoustic separation between units, KOROK Noise Control Systems meet the needs of complex acoustic demands.

KOROK Additional Noise Control Systems

| Link to System Spec | Panels | STC | STC Rating | FRR | Fire Rating | Overall System Thickness | Lining | Frame | Cavity | Flashing | Density | Application | View CAD Files in Library | MasterSpec Work Section |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NCS1 | 78mm | 36 | 36-40 | -/120/60 | 30-60 | 78mm | no linings | n/a | n/a | 400 kg/m3 | Noise control | <img decoding="async" src="https://korok.com/wp-content/uploads/2024/06/FS1-vertical-150x150.png" alt="" width="150" height="150" | 5216KC - Korok® Commercial Interior Wall Systems | |

| NCS2 | 78mm | 58 | 55-59 | -/120/120 | 120 | 175mm | 1 layer of 13mm GIB Noiseline® + R1.8 insulation | 64mm steel frame one side | Minimum 20mm | 400 kg/m3 | Noise control |  | 5216KC - Korok® Commercial Interior Wall Systems | |

| NCS3 | 78mm | 59 | 55-59 | -/120/120 | 120 | 188mm | 1 layer of 13mm GIB Noiseline® on one side with R1.8 insulation, 1 layer of 13mm GIB® Standard on the other side | 64mm steel frame one side | Minimum 20mm | 400 kg/m3 | Noise control |  | 5216KC - Korok® Commercial Interior Wall Systems | |

| KS2115-02 | 78mm | 56 | 55-59 | -/120/60 | 120 | 193 | 1 layer 10mm GIB® Standard one side, fixed to framing | 90mm timber framing one side | Minimum 15mm | 400 kg/m3 | Additional noise control |  | 5216KC - Korok® Commercial Interior Wall Systems | |

| KS2115-03 | 78mm | 56 | 55-59 | -/120/60 | 120 | 203 | 1 layer 10mm GIB® Standard each side | 90mm timber framing one side | Minimum 15mm | 400 kg/m3 | Additional noise control |  | 5216KC - Korok® Commercial Interior Wall Systems | |

| KS2115-04 | 78mm | 65 | 65-and above | -/120/60 | 120 | 308 | 1 layer 10mm GIB® Standard each side | 90mm timber framing each side | Minimum 15mm, each side | 400 kg/m3 | Additional noise control |  | 5216KC - Korok® Commercial Interior Wall Systems | |

| KS2115-09 | 78mm | 64 | 60-64 | -/120/60 | 120 | 308 | 1 layer 10mm GIB® Standard each side | 90mm timber framing each side | Minimum 15mm, each side | 400 kg/m3 | Additional noise control |  | 5216KC - Korok® Commercial Interior Wall Systems | |

| KS2115-12 | 78mm | 55 | 55-59 | -/120/60 | 120 | 193 | 1 layer 10mm GIB® Standard one side, fixed to framing | 90mm timber framing one side | Minimum 15mm | 400 kg/m3 | Additional noise control |  | 5216KC - Korok® Commercial Interior Wall Systems | |

| KS2115-13 | 78mm | 56 | 55-59 | -/120/60 | 120 | 141 | 1 layer 13mm GIB Noiseline® one side | Horizontal or vertical 28mm furring channel at 600mm centres on Rondo Betagrip clips BG02 | n/a | 400 kg/m3 | Additional noise control |  | 5216KC - Korok® Commercial Interior Wall Systems | |

| KS2115-20 | 78mm | 51 | 41-54 | -/120/60 | 120 | 136 | 1 layer 13mm GIB® Standard one side | 45mm x 45mm timber battens at 600 centers vertically or horizontally | n/a | 400 kg/m3 | Additional noise control |  | 5216KC - Korok® Commercial Interior Wall Systems | |

| KS2115-21 | 78mm | 39 | 36-40 | -/120/60 | 120 | 78 | n/a | n/a | n/a | 800 kg/m3 | Additional noise control |  | 5216KC - Korok® Commercial Interior Wall Systems | |

| KS2115-23 | 78mm | 38 | 36-40 | -/120/60 | 120 | 78 | n/a | n/a | n/a | 600 kg/m3 | Additional noise control |  | 5216KC - Korok® Commercial Interior Wall Systems | |

| KS2115-24 | 78mm | 63 | 60-64 | -/120/60 | 120 | 396 | n/a | n/a | Minimum 240mm | 800 kg/m3 + 600 kg/m3 | Additional noise control |  | 5216KC - Korok® Commercial Interior Wall Systems | |

| KS2115-25 | 78mm | 65 | 65-and above | -/120/60 | 120 | 446 | n/a | n/a | Minimum 240mm | 800 kg/m3 + 600 kg/m3 | Additional noise control |  | 5216KC - Korok® Commercial Interior Wall Systems | |

| KS2115-26 | 78mm | 64 | 60-64 | -/120/60 | 120 | 396 | n/a | n/a | Minimum 240mm | 600 kg/m3 + 400 kg/m3 | Additional noise control |  | 5216KC - Korok® Commercial Interior Wall Systems | |

| KS2115-27 | 78mm | 64 | 60-64 | -/120/60 | 120 | 446 | n/a | n/a | Minimum 240mm | 600 kg/m3 + 400 kg/m3 | Additional noise control |  | 5216KC - Korok® Commercial Interior Wall Systems | |

| KS2115-28 | 78mm | 57 | 55-59 | -/120/60 | 120 | 141 | 1 layer 13mm GIB Noiseline® one side | Horizontal 28mm furring channel at 600mm centres on Rondo Betagrip clips BG02 | n/a | 600 kg/m3 | Additional noise control |  | 5216KC - Korok® Commercial Interior Wall Systems | |

| KS2115-29 | 78mm | 58 | 55-59 | -/120/60 | 120 | 154 | 1 layer 13mm GIB Noiseline® each side | Horizontal 28mm furring channel at 600mm centres on Rondo Betagrip clips BG02 | n/a | 600 kg/m3 | Additional noise control |  | 5216KC - Korok® Commercial Interior Wall Systems | |

| KS2115-30 | 78mm | 52 | 41-54 | -/120/60 | 120 | 149 | 1 layer 13mm GIB Noiseline® each side | 45mm x 45mm timber battens at 600 centers vertically or horizontally | n/a | 600 kg/m3 | Additional noise control |  | 5216KC - Korok® Commercial Interior Wall Systems | |

| KS2115-31 | 78mm | 51 | 41-54 | -/120/60 | 120 | 136 | 1 layer 13mm GIB Noiseline® one side | 45mm x 45mm timber battens at 600 centers vertically or horizontally | n/a | 600 kg/m3 | Additional noise control |  | 5216KC - Korok® Commercial Interior Wall Systems |

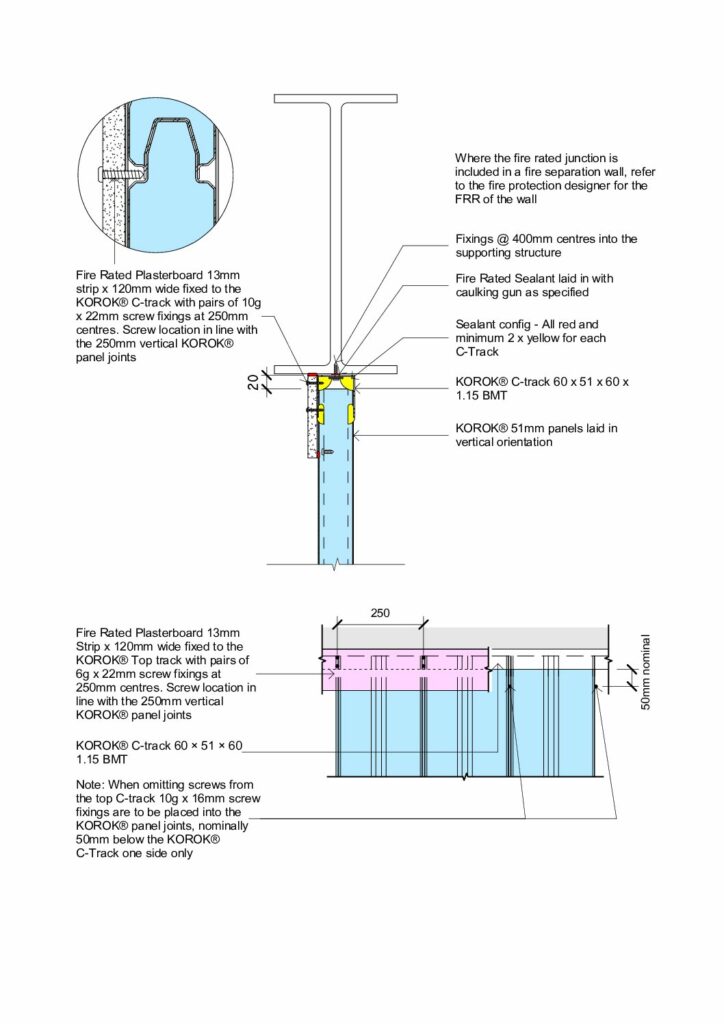

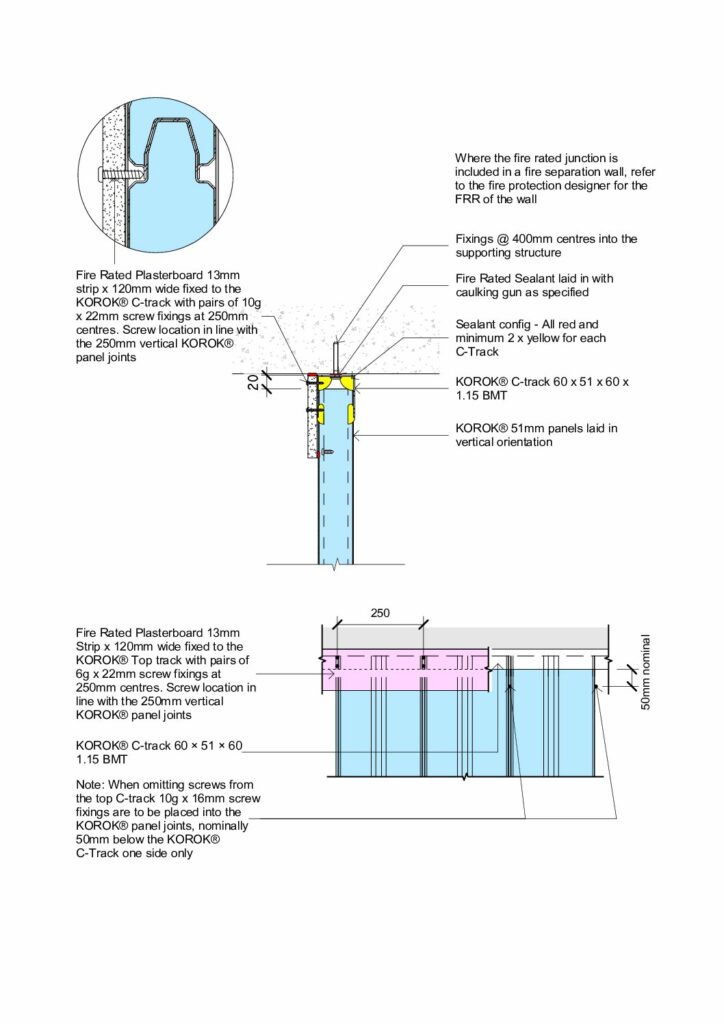

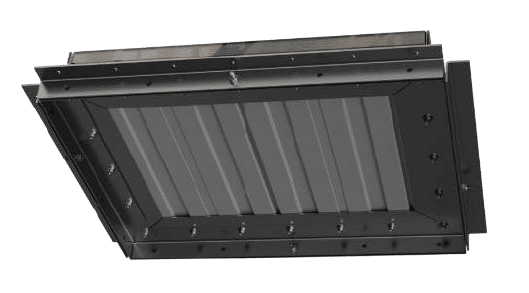

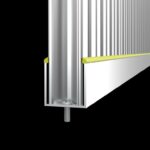

Deflection Head Details

Deflection Head Details

What Are Deflection Head Details?

Deflection head details are specialized components used in wall and partition systems to accommodate vertical or horizontal movement in a building’s structure. They are typically placed at the top of walls, allowing the structure to expand, contract, or shift without compromising the wall’s integrity or performance.

This movement can be caused by various factors, such as dead loads, live loads, thermal expansion, or seismic activity. At KOROK Building Systems, our deflection head solutions are designed to provide the flexibility and stability needed in high-performance wall systems.

KOROK deflection head details:

- Maintain Structural Integrity: Designed to allow movement in walls without damaging the structure, these details help prevent cracking or separation in response to building movement.

- Ensure Fire and Acoustic Performance: KOROK deflection heads are rigorously tested to retain fire resistance and acoustic ratings, even with movement, maintaining protection in all conditions.

- Seismic Readiness: In New Zealand, where seismic activity can impact building structures, our deflection head designs are engineered to absorb and adjust to seismic forces, supporting safe and resilient structures.

Dead and live loads can cause significant deflection in some structures. KOROK® can provide deflection C-track details where deflection loadings are considered.

Whether used in commercial or residential projects, KOROK’s deflection head details meet the highest industry standards, offering a reliable solution for builders, architects, and contractors who prioritize safety, performance, and durability.

KOROK Fire Sealant

KOROK Fire Sealant

Welcome to our comprehensive guide on KOROK Fire Sealant, an essential product for ensuring safety and integrity in building structures. Incorporating KOROK Fire Sealant into your projects ensures compliance with fire safety standards and enhances structural durability.

Sealant Application Video

Learn how to apply sealant to a KOROK wall quickly and efficiently. This step-by-step video shows the right technique to ensure a clean, professional finish that maintains the fire and acoustic performance of your wall system.

Sustainability

Sustainability

At KOROK, we aim to balance industry and nature. We’re committed to providing high-performance products with a minimised environmental impact.

Our Commitment to Waste Reduction

At KOROK, we focus on reducing waste and being environmentally responsible. Our efficient manufacturing processes and thoughtful product designs help us provide reliable, high-performance solutions.

Reducing Waste

Made to Order

Our panels are manufactured to order, ensuring minimal waste. This custom approach means minimal off-cuts and no unnecessary waste, as each panel is designed to fit specific job requirements perfectly.

Fully Reusable

KOROK panels are designed for reuse. They can be taken down and reassembled multiple times, making them ideal for reconfiguring warehouse or retail spaces. This reusability significantly enhances their ecological friendliness, reducing the need for new materials and minimising waste.

Fully Recyclable

When a KOROK panel reaches the end of its life cycle, it doesn’t need to end up in a landfill. The panels can be disassembled for recycling: the concrete core is crushed and repurposed, and the steel casing is recycled. This closed-loop process ensures that our products contribute to a sustainable future.

Environmental Product Declarations (EPDs)

We are proud to announce the completion of our Environmental Product Declarations (EPDs), a testament to our commitment to transparency and sustainability. One for our Galv panel and one for our Colour panel.

What is an EPD?

An Environmental Product Declaration (EPD) is a certified, independently verified summary of a product’s environmental impact over its entire life cycle. It evaluates:

- The materials extracted from the earth.

- Energy used in the production, transportation and installation.

- The environmental impacts of using, disposing, or recycling the product.

The EPD covers a range of environmental indicators, including the potential for carbon emissions, air and water pollution, and depletion of natural resources. Based on international standards (ISO 14025 and EN 15804 for building materials), our EPD is independently verified, making it a trusted and reputable source of information. It is recognized by industries, companies, and governments, and is often specified in tender documents and contracts.

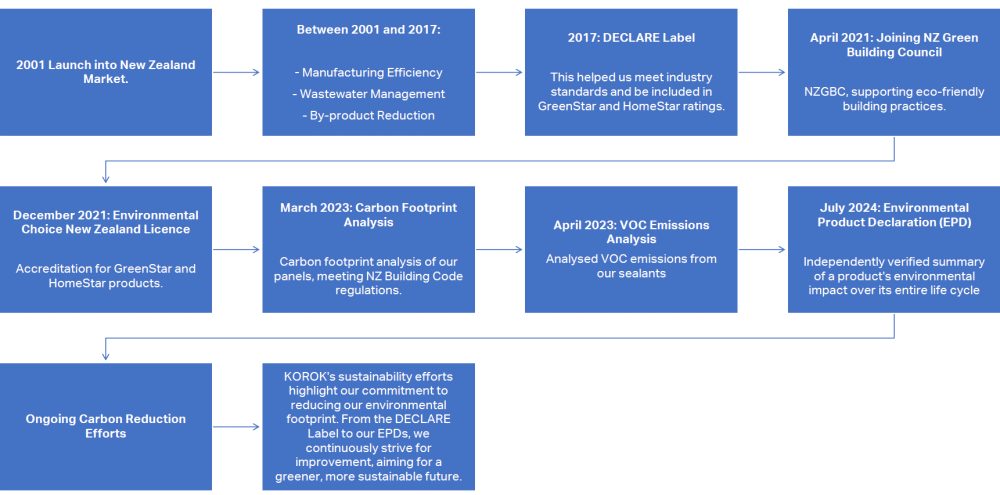

KOROK’s Sustainability Journey

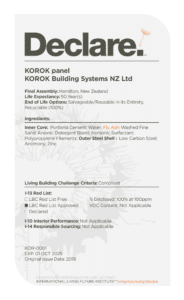

Officially Recognised

A DECLARE LABEL ANSWERS THREE QUESTIONS:

- Where does a product come from?

- What is it made of?

- Where does it go at the end of its life?

Declare is a transparency platform and product database that is changing the materials marketplace.

FAQs

Frequently Asked Questions

There is a 15-year warranty from KOROK® Building Systems NZ Limited for correctly installed walls. Full details can be read here.

KOROK® panels have been used for over 20 years. You can find them in nearly every cinema in NZ (because their acoustic qualities are so good); in many high-rises around the lift shafts and stairs (because they offer such great fire protection); and between many terraced houses and apartments (for both fire and acoustic protection).

KOROK® panels are made from a galvanised steel shell, filled with aerated concrete. They are NZ-made and are fully recyclable. KOROK® panels come in two thicknesses 51mm and 78mm.

The building code requires a certain level of acoustic protection between terraced houses (STC 55). Many builders go above and beyond this and we have terraced housing systems up to STC 69. KOROK® panels are designed so that you can’t hear your neighbours and are also good at blocking lower base noise. Remember that it is used in most cinemas in New Zealand so that Avengers: Endgame doesn’t impact on A Quiet Place.

The building code requires a certain level of fire protection between terraced houses (30 minutes). Most builders go above and beyond this providing you and your property with at least an hour of fire protection.

Our systems are used in a wide range of projects, including:

- Residential: Apartments and terraced housing

- Commercial: Retail stores, warehouses, factories, and office buildings

- Infrastructure: Airports, libraries, cinemas, and control towers

Check out our Case Studies for project examples.

KOROK panels provide up to a 2-hour fire rating (FRR -/120/120) depending on the system and configuration. For detailed fire rating information, visit our Technical Resources or use our System Selector tool for quick navigation.

KOROK systems are designed for fast and efficient installation. With fewer lining requirements and lightweight materials, our single-panel systems save time and reduce construction complexity. See Installation page

Yes! We’re focused on waste reduction and improving our environmental footprint. Our panels are BRANZ appraised and have Environmental Product Declarations (EPDs), ensuring transparency about our products’ lifecycle impacts. Learn more on our Sustainability Page

The System Selector is a tool that allows you to quickly find KOROK systems and download relevant CAD files in just three clicks—no login required. We value your privacy, so we don’t collect any data from your visits.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.dsfsfdfdsfds