KOROK Access Panel – Safe Removal & Reinstallation Procedure

⚠ WARNING – HEAVY PANEL (33 kg)!

IN ACCORDANCE WITH NEW ZEALAND HEALTH & SAFETY REQUIREMENTS

- 33 kg Weight: This panel is heavy and may cause serious injury if not handled correctly.

- Team Lift Mandatory: Always use at least two people or appropriate mechanical lifting equipment.

- Wear Proper PPE: Use gloves, safety footwear, and any other required personal protective equipment.

- Follow Lifting Procedures: Ensure you follow all site-specific and WorkSafe New Zealand guidelines, including a proper risk assessment before lifting.

- Secure Installation: Confirm that the panel is securely supported during movement and installation.

Failure to use correct lifting methods and PPE may result in severe injury or property damage.

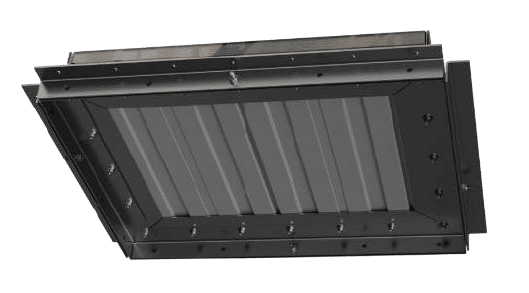

- Applicable Panel Type: Fire-Rated Ceiling Access Panels

- Panel Weight: Approx. 33 kg (Team lift required)

- PPE Required: Gloves, safety boots, hard hat, safety glasses

STEP 1. PREPARATION & SAFETY CHECKS

- Ensure all relevant site safety protocols and WorkSafe NZ guidelines are followed.

- Review the access panel warning label and lifting instructions prior to beginning.

- Conduct a job safety analysis (JSA) or task risk assessment.

- Inspect the work area for overhead hazards and confirm safe clearance for panel lowering.

- Confirm required PPE is worn and in good condition.

- Gather appropriate tools:

- Socket set or spanners

- Mechanical lifting aid (optional but recommended)

- Clean drop cloth or secure storage pallet

STEP 2. SUPPORTING THE PANEL

- Before any bolts are loosened, ensure the panel is securely supported by:

- Two competent personnel (manual lift), or

- An approved mechanical lifting device.

- Support the panel from beneath to prevent any unplanned movement.

STEP 4. PANEL REMOVAL

- Once weight is fully supported and remaining bolts are accessible, remove the final two bolts.

- Carefully lower the panel straight down, ensuring no twist or torque is applied to the frame.

- Immediately place the panel on a prepared soft surface or pallet to avoid damage.

- Store panel in a secure, dry, and protected area free from impact risk.

STEP 5. CONDITION INSPECTION (PRE-REINSTALLATION)

Perform a full visual and physical inspection of the following components:

- Hatch door surface for warping, dents, or cracks

- Frame integrity including weld points and connection tabs

- Intumescent seal – check for continuous seal and any cracking or displacement

- Promatect® fire board – check for chipping, delamination, or moisture ingress

Replace any damaged or non-compliant components before proceeding with reinstallation.

- REINSTALLATION PROCEDURE

- Position the access panel under the aperture using team lift or lifting device.

- Align the panel with the original bolt holes and insert bolts at each angleline.

- Once Securing nut and bolt assys are secured, reinstall remaining bolts in a crisscross pattern to ensure even loading.

- Torque all fasteners to manufacturer-recommended specification if available.

- Visually verify that the panel is flush with the ceiling and that all mechanical fixings are secured.

Contact our Installation & Technical Support Manager for any questions you may have.